Laser Cutting Paper

Laser Cutting Paper Machine

Products Description

This state-of-the-art machine utilizes advanced laser technology to cleanly cut intricate shapes and designs with unmatched accuracy and speed, making it a must-have tool for any paper artist or crafting enthusiast. With its user-friendly interface and easy-to-operate software, our Laser Cutting Paper Machine makes it easy to create intricate designs that were previously challenging to produce by hand. The machine can cut through a wide range of paper materials, including cardstock, vellum, and more, making it versatile and adaptable for all your crafting needs.

Features and performances

| 1 . Non-contact processing: can be marked on any regular or irregular surface with a fine mark. |

| 2 .Wide range of materials: can be marked on paper, plastic, ceramics, glass, leather and other materials of different types or different hardness. |

| 3 . low running cost: marking speed and marking once formed, very few consumables, thus low running cost. |

| 4 .Can be integrated with other equipment on the production line, to improve the automation of the production line. |

| 5 .Clear, permanent and indelible marking, beautiful and effective anti-counterfeiting. |

| 6 .Long service life, no pollution. |

| 7 .Fast marking speed, greatly improving production efficiency |

Applications

| greeting cards | wedding invitations | sugar boxes | paper cutting |

| 3D paper carving lamps | painting templates | paper crafts | bamboo |

Parameters

|

NO. |

Name |

DS-LMC series Galvo laser system |

|

1 |

Machine model |

DS-LMC150/DS-LMC250 |

|

2 |

Max laser power |

150W/250W |

|

3 |

laser wavelength |

10.6μm |

|

4 |

Beam quality |

<1.2㎡ |

|

5 |

Duty cycle limit |

≤60% |

|

6 |

Min.line width |

0.35mm(depend on the material) |

|

7 |

Min.character size |

2mm |

|

8 |

Max marking speed |

≤8,000mm/s |

|

9 |

Working area |

400x400mm/600x600mm/750x750mm |

|

10 |

Cooling |

Water cooled |

|

11 |

Working environment temperature range |

5~35 ℃ |

|

12 |

Humidity range of working environment |

< 70% No condensation |

|

13 |

Power supply |

220V,50/60Hz |

|

14 |

Power consumption |

<6KW |

Introduce of machine

Laser cutting is a high-precision process that can create complex designs and patterns on paper.

The most common question when it comes to laser cutting paper is this- "How can you laser cut paper without burning it?"

Good process control and optimal parameters are the answers for laser cutting paper with no edge burns.

CO2 dynamic marking machine principle

CO2 laser marking machine is often called gas laser marking machine, CO2 laser is an infrared frequency band wavelength of 10.64um gas laser, using CO2 gas charged into the discharge tube as the medium for generating laser, when the electrode is added with high voltage, the discharge tube in the glow discharge, it can make the gas molecules release laser, the laser energy amplified to form the laser beam on the material processing.

Through the computer the laser beam is then amplified to form a laser beam for processing the material, and the laser beam is automatically marked by computerised control of the oscillator to change the optical path. The laser beam is used to irradiate the surface of the material and the light energy is instantly converted into heat energy, causing the surface of the material to melt or even vaporise instantly, thus forming the mark.

machine details:

Power parameters selection

The laser uses a radio frequency imported laser tube with a peak power of 330W, so we need to prevent the power from being too high when cutting cardboard and causing the paper to burn black and yellow, which is not perfect.

Speed

Different power use will match the speed will be different, we use a high-speed dynamic scanning system, so the speed we cut ordinary cardboard using a range of 300-1000mm / s, depending on the processing width of the power used at the level of proportion and different.

Frequency

According to the use of laser power and speed we will set the need for frequency, generally set at 3KHZ-20HKZ, when the frequency is set higher, the laser power will be weakened at the same time;

Laser cut paper projects

It has been around for a long time, but paper crafting has been revolutionised with the introduction of laser cutters. Depending on your budget, laser cutter and design expertise, you can start making basic papercrafting projects and level up with each project.

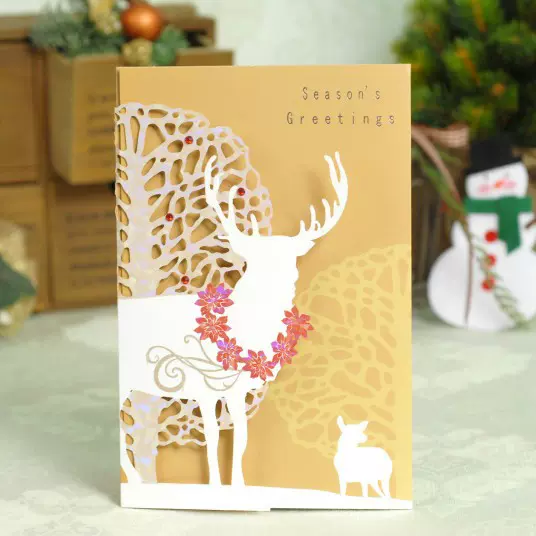

Greeting Cards

Shipping and Package

FAQ

Q: Can you laser engrave a photograph on paper?

Q: Can you perform vector engraving on paper?

Q: How can you ship a laser to me ?

Why choose us?

- Our factory in China uses the latest technology to produce laser marking machines that are innovative and efficient.

- We provide high quality and value professional products and services to our customers, and win their understanding, respect and support with our sincerity and strength.

- We are a leading supplier and manufacturer of laser marking machines that are made in China.

- We take 'Quality Standards, Innovation, Continuous Improvement, Customer Satisfaction' as our quality policy, take the recruitment of talents as the foundation of the enterprise, and regard improving product quality as our mission. We provide you with a one-stop service for Laser Cutting Paper at a reasonable price. Welcome domestic and foreign customers to call and negotiate.

- Our laser marking machines are designed to offer high performance and efficiency while being easy to use and maintain.

- Our company promises to become a bright star in the industry with excellent quality, perfect service and the alliance of all walks of life.

- We take pride in delivering laser marking machines that exceed the expectations of our clients.

- We actively build a more reasonable production layout planning, stricter and higher process quality control and requirements, laying the foundation for another leapfrog development.

- Our laser marking machines are designed to be intuitive and user-friendly, making them easy to use for operators of all skill levels.

- We bring in suitable talents and excellent talents who agree with the corporate culture to inject a constant stream of living water for the development of the enterprise.

You Might Also Like

Send Inquiry